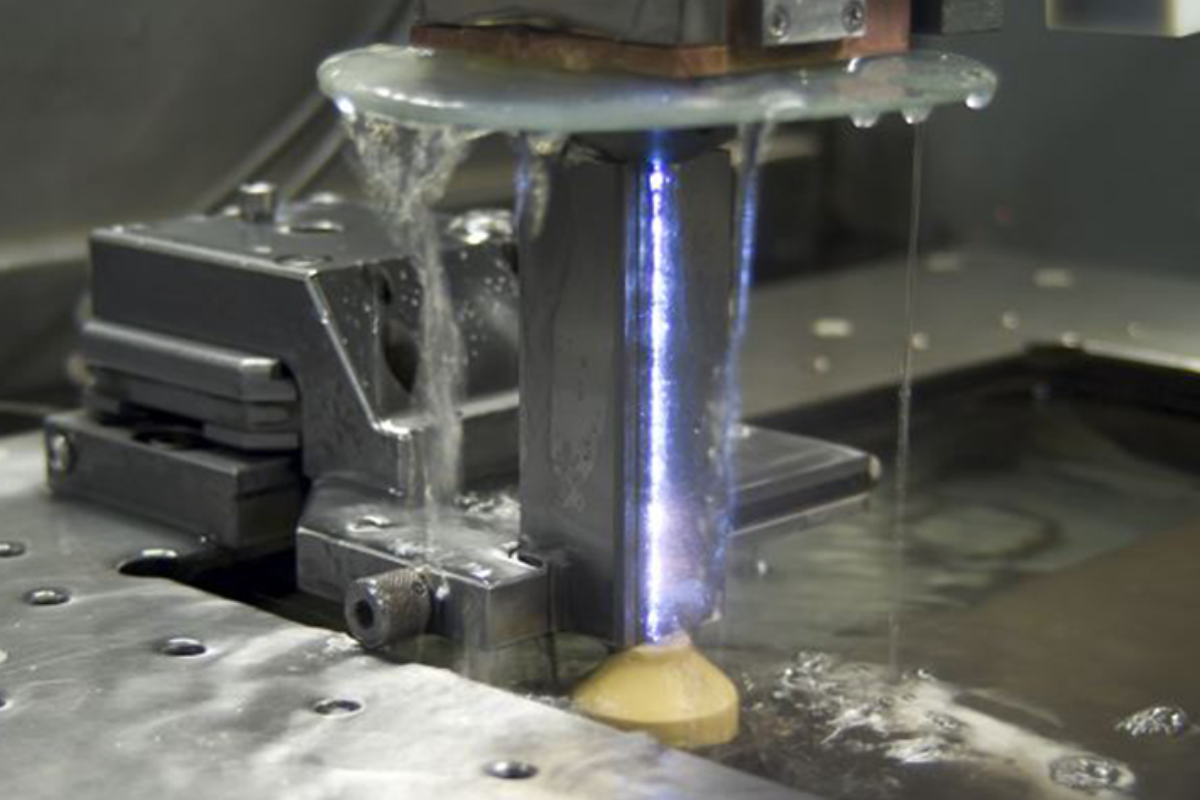

Wire Cut EDM is a process of cutting electrically conductive materials using electro thermal mechanism.

Working Principle: A very thin wire of brass is passed through a small predrilled hole through the workpiece using wire feed mechanism. As the current is supplied, the spark is produced between the wire and workpiece gap which removes material of the workpiece.

Dielectric fluid is passed over the workpiece and the wire.

Construction:

- Filter

- Pump

- Wire

- Wire feed mechanism

- Wire reel

- NC control unit

- Dielectric fluid

Wire Material: Brass, Copper , Tungsten, Zinc

Wire Diameter: 0.02 to 0.3 mm

Applications:

- Intricate components for aerospace and electric industries

- Profile cutting

- Machining of sheet metal die

- Gear teeth cutting

- Cylindrical objects cutting

Advantages:

- Any electrically conductive material can be machined

- tool and workpiece are free from cutting forces

- Good surface finish

- Edge machining and sharp corners are possible

- Negligible wear of electrode

- High production rate

- Does not leave any chips or burrs

Limitations:

- Non electric conductive materials cannot be machined

- Suitable for only small workpieces

- Perfect square corner cannot be made as wire have some diameter

- Very high power requirement

No responses yet